Pick-by-Vision

picking via pick-by-vision

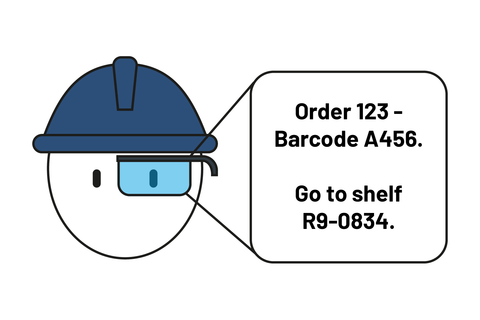

Picking work based on data glasses: Pick-by-Vision is a special picking process in which the picker uses data glasses and special information to assemble items for customer or production orders.

definition

In the pick-by-vision picking process, the picker is given information about the desired items via data glasses. The so-called smart glasses transmit information about the respective order to the picker. The glasses also inform the picker where the item being sought is located: shelf, pallet, compartment or similar. This is made possible by the use of augmented reality (AR). The user's normal field of vision is expanded to include virtually generated information.

Depending on the software, the glasses can tell the employee the shortest route to the relevant storage location, thereby increasing operational efficiency. A tracking system usually records the picker's location.

technical equipment

In order to use the pick-by-vision process, certain technical requirements are necessary. These include the following components:

- camera

- processor for calculating input and output

- sensors for orientation

- display for displaying augmented reality

- sensors for determining position

- database

- Interfaces to the warehouse management system, ERP system

Advantages

The pick-by-vision process offers several advantages.

- Both hands free for picking

- Efficient work by saving travel time, base time, dead time

- Increased picking speed

- Pick list and article descriptions in digital format

- Audiovisual support

- Low training costs

- Immediate inventory reconciliation with the warehouse system

- Can be used in various storage systems

- Navigation to the pickup location

- Low susceptibility to errors

The pick-by-vision process combines the advantages of the pick-by-voice and pick-by-light processes.

Disadvantages

The pick-by-vision process also has a few disadvantages.

- Data glasses must be suitable for industrial use

- When there are several barcodes next to each other, fixing and correctly capturing them is difficult and requires practice

- short battery life; external batteries required

- For those who wear glasses, there are additional costs for the lenses

- Dizziness may occur

- Comprehensive Wi-Fi required

- Higher workload due to high levels of visual information processing

- Previous fatigue symptoms due to high concentration and visual strain

- Possible increase in the risk of accidents due to focus on virtual information

The error rate in order picking is crucial for logistics companies. The pick-by-vision process reduces the error rate noticeably. Nevertheless, it is important to adapt the working environment and the organization, as the cognitive load on the order pickers is significantly higher. This is due to the unfamiliar visual load on the one hand, coupled with an increased flood of information on the other, which is fed into the worker's field of vision via the smart glasses.

development status and area of application

Pick-by-vision systems are actively used today. The rapid implementation is based on the fact that the integration of data glasses into existing warehouse systems is easy.

The pick-by-vision process is used in large production or logistics companies - Bosch, PepsiCo or DB Schenker.