refilling the pallet truck oil

The lifting and lowering of the forks of a hand pallet truck is done via hydraulics. In order for hydraulic pressure to be built up, there must be sufficient oil in the industrial truck.

The hydraulic oil transfers the pressure from the hydraulic cylinder to the lifting cylinder. This moves. The oil is not compressible, which means that the pressure from the pump is transferred directly to the lifting device of the lift truck. You can find out how to easily top up the oil level of the lift truck yourself and what you need to pay attention to in this step-by-step guide :

1

Get suitable oil. Basically, you should always top up the oil that is already in the hydraulic system. If you don't know the type of oil, read the operating instructions for your pallet truck. Most devices can be filled with hydraulic oil HLP 46 or hydraulic oil HLP 32. Please note that there is a special, thinner hydraulic oil for use in cold areas or in areas with temperature fluctuations. Read more about this: Which oil for pallet trucks?

2

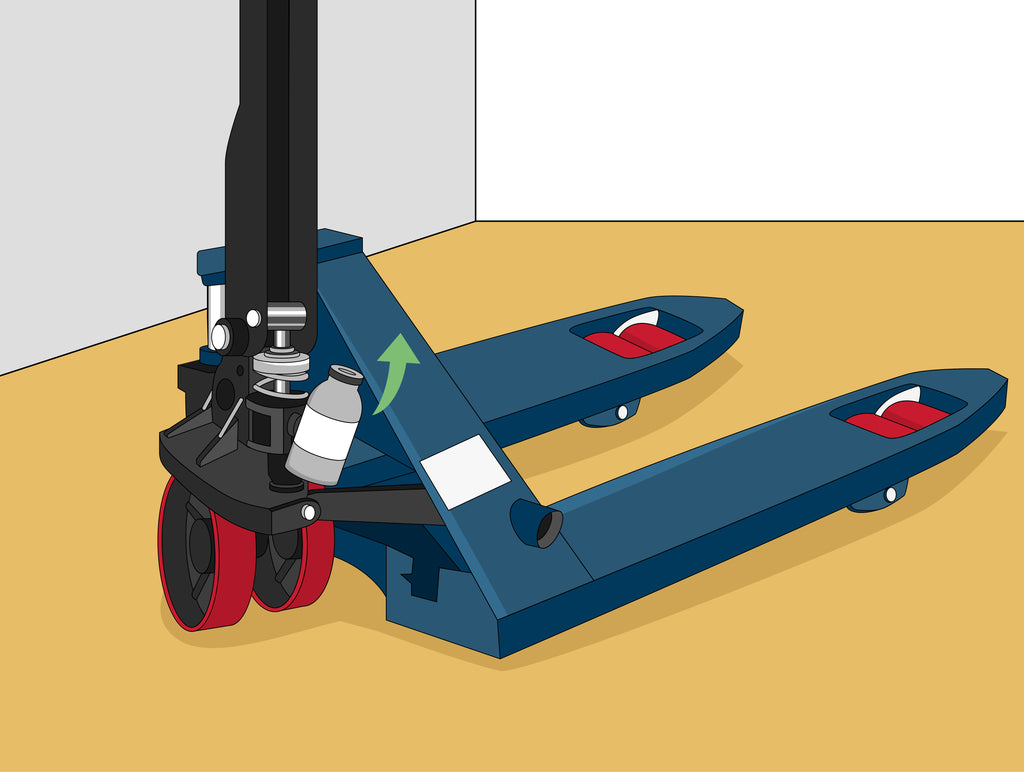

Safe footing. First, make sure you park the pallet truck on a hard, level surface. Then move the control lever to the "lower" position to fully lower the forks of the pallet truck.

3

Locate the oil tank. To easily access the hydraulics of the pallet truck, turn the lever handle of the low lift truck to the side as far as it will go. The hydraulic housing is located on the drawbar, often near a small sight glass that is used to check the oil level. The location of the hydraulic oil tank is specified in the operating instructions.

4

Remove the protective cap/screw. Use a screwdriver to loosen the screws. Remove the protective cap. It is located above the oil tank. Then remove the seal set on the piston, also known as an O-ring, and the cover underneath. You can carefully use a screwdriver to loosen it. On some lift truck models, you do not need to remove the protective cap to refill the oil, just loosen a screw on the hydraulic housing.

5

Top up the oil. Now carefully top up the oil with the appropriate amount. As a rule, pallet trucks only need a very small amount of oil (no more than 0.3 liters). If there is no sight glass on the device, you should use the lower edge of the filler neck as a guide.

6

Test the lifting function. Pump the pallet truck 10 to 15 times to bleed the hydraulic unit and check whether the forks can be raised and lowered as usual. Then close the tank cap and refit the protective cap properly. Your pallet truck is ready for use again. If the forks still do not lift, add more oil and repeat the pumping process. Otherwise, the problem could be due to dirty oil. An oil change is necessary at this point.

Questions & Answers

What are the reasons for oil loss?

Under normal operating conditions, there are few reasons why the hydraulic oil in the pallet truck decreases. One possible reason for the oil loss could be signs of wear on the seals. If this is the case, you should definitely replace them. Sealing rings can usually be ordered directly from your pallet truck dealer and will be delivered within a few days.

How often should the oil level be checked?

Regular inspection of the oil level is important. The oil should be changed approximately every 3 to 6 months, depending on the intensity of use.

How do you change the oil in a pallet truck?

To change the oil, all you need to do is lay the pallet truck on its side and let the used oil drain out completely (warning: hazardous waste!). Put the pallet truck back upright and then fill it with new oil. Follow the instructions above for the individual steps.

Which pallet truck do I need?

Are you still not sure which pallet truck is right for you? Tell us your requirements in a few questions and we will send you a suitable offer within 24 hours - free of charge and without obligation. Start the test now: Which pallet truck is right for me?